October 2, 2025 /

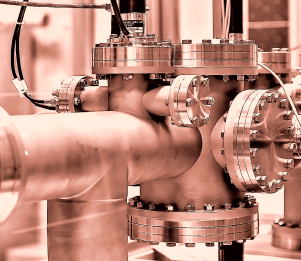

Room for gas equipment

Gas equipment imposes strict requirements on the premises where it is installed. Incorrect placement of the boiler can lead to safety violations and serious risks. In this article, we review in detail the EVS building standards and fire safety regulations that must be followed during installation. Special attention is given to ventilation, chimney, windows, doors, and power supply requirements. We explain where boilers are allowed to be installed and where they are strictly prohibited. This overview will help you properly prepare the boiler room and avoid problems during inspections.

When designing gas equipment in a building, it is necessary to rely on:

- the regulation “Requirements for the gas installation and construction of the gas installation”;

- the “General fire safety requirements”;

- the “Fire safety requirements for buildings and their parts”;

- the standards EVS 844, EVS 839, EVS 812, and other norms relating to fire safety of the building.

The basis for technical reconstruction of a building or premises must be a construction project approved in the prescribed manner. A room where, according to the project, a gas installation is built and compliant gas equipment is installed in accordance with safety requirements is not considered a fire- or explosion-hazardous room.

Gas heating equipment may be installed in a utility room of a single-family house, semi-detached house, or terraced house, as well as in the basement of a residential building. When installing gas heating equipment in the basement, special requirements apply: fireproof sectioning, non-combustible intermediate structures, the presence of a window (door, hatch), etc.

For gas heating equipment up to 25 kW that the manufacturer allows to be installed directly in living rooms, all requirements of EVS 812-3 must be applied, although no additional construction restrictions (e.g. fire resistance) apply to the premises. Discharging flue gases into ventilation ducts is not permitted.

Gas equipment (except for radiant heaters and air heating units with locked or externally placed controls) must not be installed in common areas: corridors, hallways, foyers, lobbies, stairwells, etc.

Devices must not be installed in rooms where flammable liquids or combustible substances are stored. Water heaters and boilers must be placed so that they are protected from freezing.

Equipment located in a shared attic must be placed in a separate room. Equipment installed on the roof of a building must be protected from weather effects.

Exits from rooms (including from attics) into common areas (corridors, stairwells) must remain unobstructed. Permanent staircases and ladders to access attics are considered common passages.

Note: for early detection of gas leaks, a gas detector may be installed in basements. If the threshold is exceeded, a relay can trigger a siren, ventilation, or shut off the gas supply with a magnetic valve.

Requirements for rooms intended for gas boiler installation

- Ceiling height not less than 2.2 m.

- Area of at least 4 m² per boiler.

- External door width not less than 80 cm.

- Window for natural lighting (0.3 m² of window per 10 m³ of room volume).

- Outdoor air inlet opening — at least 5 cm² per 1 kW of boiler nominal power, or 15 cm² per 1 kW if air is drawn from inside the building.

- For chimneys: to ensure proper draft and avoid backflow, the top cut of the chimney should be above the roof ridge.

- The chimney (or chimneys for two boilers) must have a cross-section corresponding to the installed equipment. In any case, the chimney cross-sectional area must not be smaller than the boiler’s flue outlet area.

- Each chimney must have an inspection opening located at least 25 cm below the chimney inlet.

- For boilers with turbo burners, the chimney may exit through the side wall, but there must be no opening windows or doors of living spaces, building corners, or overhanging parts near the flue (minimum distances depend on equipment power).

- Natural ventilation duct at the top of the room.

- Supply and return pipes of the heating system.

- Cold water supply pipeline.

- Sewer drain.

- Power supply source connected to a separate 220V 20A circuit breaker of the main switchboard.

- Grounding conductor of the house system.

- Gas pipeline section with a gas shut-off valve for each boiler.

- Walls must be plastered, floor leveled.

Chimney

Modern chimneys: requirements for materials, shape, and insulation for boilers

Heating system automation

How automation maintains comfortable temperature and protects the heating system

Gas equipment – part 3

Efficient heating: boiler capacity calculation and an overview of alternative heaters

Gas equipment – part 2

Condensing boilers: how they work, efficiency, and when they pay off.

Gas equipment – part 1

Modern gas boilers: floor-standing and wall-mounted solutions for houses and apartments

What kinds of heating devices are there?

Radiators, convectors, and underfloor heating: comparing design, heat output, and areas of application.