October 2, 2025 /

Heating system automation

Modern heating systems are increasingly equipped with automation that controls temperature and saves resources. From a simple thermostat to complex weather-compensated controllers — the options vary, but the goal is always the same: comfort and safety. In this article, we explain how automation works with heating circuits and heat generators. We clarify what boiler rotation is and why multi-stage burners are needed. You will learn the advantages of installing controllers and how they affect gas consumption. This knowledge will help you decide whether it is worth investing in “smart” heating control in your case.

Heating system management tasks have been solved for a long time, and nothing radically new seems to appear in this area. But as many companies as there are, so many approaches exist. We tried to simplify the understanding of the logic and explain the general principles.

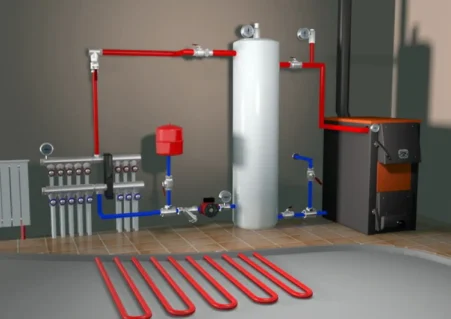

In a comfortable hydraulic heating system, heat is transferred from the place where it is generated (boilers and other heat generators) to where it is dissipated (radiators, underfloor heating, fan heaters, domestic hot water boilers, and other heat consumers). This process must be under control. Controllers (regulators) manage the coordinated operation of heating systems.

A heating system controller can manage:

- a) Heat consumers (radiators, underfloor heating, fan heaters, domestic hot water boilers, and other heat consumers);

- b) Switching on/off heat generators, such as boiler burners.

Managing heat consumers

The load on heat generators depends on how much thermal energy is demanded. Each consumer has its own heating circuit or zone consisting of a supply pipe, return pipe, pump, and control element (valve, mixer).

The controller, depending on indoor and outdoor temperatures, the circuit temperature, and their deviation from the setpoint, sends a signal to the control element or pump. This signal can be:

- discrete (on/off) for valves or pumps;

- pulse (more/less/stop);

- or analog (a specific flow value) for the mixer.

As a result, the water flow in the circuit is regulated — it is opened or shut off, or the supply and return water are mixed.

Managing heat generators

Heat generators — boilers — may have single- or two-stage burners. Whether one or two stages are on determines the boiler’s output. The stages are managed like separate boilers. Their difference from independent boilers matters only for rotation.

Rotation means periodically changing the order of boiler activation to reduce uneven load. Burner stages cannot be rotated.

The controller managing heat generators must ensure that the boiler circuit temperature satisfies the demand of any consumer.

The consumer circuit temperature can be:

- fixed,

- or calculated by the controller depending on the situation (for example, by outdoor temperature graph, or when switching from economy to comfort mode).

What is required from a heating system controller?

For users, it is important that the controller can:

- maintain comfortable room temperature;

- save energy (and thus money);

- prevent system failures and keep it operational.

Functional types of heating control devices

- Thermostats. The simplest regulators. Installed in the living area. Depending on air temperature, they switch the boiler burner or circuit pump on/off, or open/close the mixing valve.

- Heat-carrier temperature controllers. Maintain the set temperature in one or more heating circuits. They work via a heat-carrier sensor and control the circuit’s mixing valve.

- Weather-compensated controllers. Increase or decrease the temperature of the heat carrier depending on outdoor temperature. They connect to an outdoor air sensor, a heat-carrier sensor, and a room thermostat. A temperature graph is set — the dependence of the heat-carrier temperature that ensures indoor comfort on the outdoor temperature.

Chimney

Modern chimneys: requirements for materials, shape, and insulation for boilers

Room for gas equipment

Standards for boiler rooms: from air inlets to minimum façade distances

Gas equipment – part 3

Efficient heating: boiler capacity calculation and an overview of alternative heaters

Gas equipment – part 2

Condensing boilers: how they work, efficiency, and when they pay off.

Gas equipment – part 1

Modern gas boilers: floor-standing and wall-mounted solutions for houses and apartments

What kinds of heating devices are there?

Radiators, convectors, and underfloor heating: comparing design, heat output, and areas of application.