October 2, 2025 /

Gas equipment – part 3

When designing a heating system, it is important not only to choose a boiler but also to correctly calculate its capacity. A miscalculation will result either in insufficient heating or in excessive gas consumption. In this article, we also review alternative solutions — gas air heaters and infrared heaters. They are used in large spaces, production workshops, warehouses, and shopping halls. Such devices help reduce costs and increase heating efficiency. We will explain how they work and in which cases they are the most reasonable choice.

Gas is supplied via the pipeline to the burner, burns completely in the stream of heated air, and, mixing with it, transfers combustion heat almost 100%. The heat of the burnt gas heats the heat exchanger, which is forcibly blown by the airflow from the fan.

Gas air heaters are equipped with temperature controllers. According to the set temperature, the warm-air generator operates directly at the point of heat consumption. Decentralization and ease of regulation according to the set temperature are precisely the characteristics that make such a system energy-saving.

They are used in most industrial facilities, shopping centers, administrative buildings, warehouses, and many other premises.

Infrared heaters

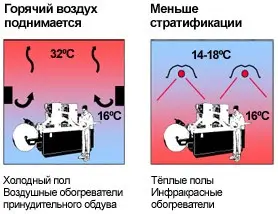

All modern infrared heaters work similarly to the Sun. With a high surface temperature, the heaters use the physical properties of electromagnetic waves to transfer thermal energy to all objects located within the device’s operating zone. Heated objects, in turn, radiate the accumulated heat into the surrounding space, warming it by convection.

Energy saving is achieved by eliminating the intermediate heat carrier — air — from the heating process. Electromagnetic waves transfer heat directly to surrounding objects.

The second positive aspect of this type of equipment is the accumulation of heat inside the objects within the emitter’s range.

Thus, a kind of “heat reservoir” is created, capable of maintaining comfortable conditions for some time even after the heater is switched off. This property of radiant heating can be used for additional energy savings during non-working hours (lunch breaks or nighttime), when the system is switched to economy mode, maintaining a minimal positive temperature and preventing the room from cooling down.

Infrared heaters are best suited for heating:

- car repair workshops;

- agricultural buildings;

- indoor tennis courts;

- manufacturing facilities;

- recreational and entertainment areas;

- showrooms;

- shops;

- warehouses;

- and many other types of premises.

Chimney

Modern chimneys: requirements for materials, shape, and insulation for boilers

Heating system automation

How automation maintains comfortable temperature and protects the heating system

Room for gas equipment

Standards for boiler rooms: from air inlets to minimum façade distances

Gas equipment – part 2

Condensing boilers: how they work, efficiency, and when they pay off.

Gas equipment – part 1

Modern gas boilers: floor-standing and wall-mounted solutions for houses and apartments

What kinds of heating devices are there?

Radiators, convectors, and underfloor heating: comparing design, heat output, and areas of application.