October 2, 2025 /

Какие бывают отопительные приборы?

When choosing heating devices, homeowners and apartment owners face many questions. Radiators, convectors, or underfloor heating — each option has its advantages and disadvantages. The modern market offers cast-iron, steel, aluminum, and bimetallic radiators, differing in design, durability, and price. The right choice affects not only comfort but also the efficiency of heating. We explain how different devices work and give guidance for comparison. This article will help you figure out which devices are best for you, considering operating conditions and budget.

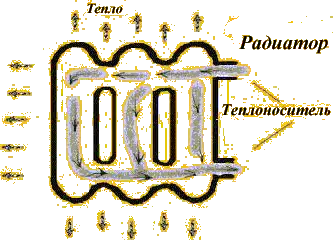

Radiators — by their design, they have a relatively large volume and always contain a lot of hot heat carrier. Because of this, they release heat mainly through radiation (fireplace effect).

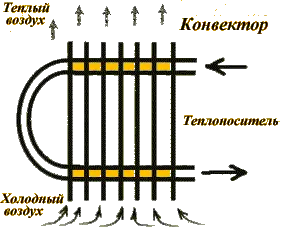

Convectors — release heat mainly due to air circulation through them. The heat carrier flows through the convector pipe, heating the “accordion” surfaces. Air passes through the convector from bottom to top, warming up from numerous heated surfaces.

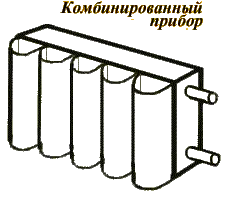

There are heating devices that combine the properties of radiators and convectors. Their flat storage panels hold a large amount of hot water, while their ribbed surfaces provide additional heat exchange. Thus, they combine both methods of heat transfer — radiation and convection.

Further, all heating devices, regardless of heat transfer method, will be called radiators — it’s simpler.

What types of radiators are there?

- Cast iron — provide good heat transfer and are resistant to rust, withstand high system pressure. Disadvantages: heavy and not always suitable for modern design.

- Aluminum — lightweight, high heat output, aesthetic, but expensive and sometimes cannot withstand high pressure.

- Bimetallic — consist of a steel tube carrying the heat carrier and an aluminum casing. Steel withstands high pressure, aluminum transfers heat quickly. A modern and reliable option.

- Steel panel — optimal in price and heat output. Currently the most popular. Manufactured to a unified standard, they look similar.

Such radiators are made of high-quality cold-rolled steel. They consist of two or three flat panels with heat carrier inside and ribbed surfaces between them. The design provides combined heat transfer: large panels work through radiation, while ribbed elements provide convection.

Radiators can have bottom or side connections:

- Bottom connection — more aesthetic and convenient for installation.

- Many models are equipped with a built-in thermostatic valve, allowing connection of a thermostat for automatic temperature control.

What is underfloor heating?

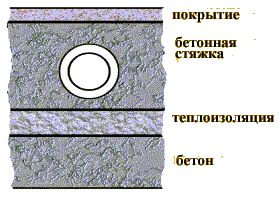

For underfloor heating, a pipe is laid under the floor, through which the heat carrier flows. It evenly warms the floor surface and the room air. To “pump” the heat carrier through the long circuit of a thin pipe and avoid overheating, an additional pump and mixing unit are installed in the boiler room.

More about underfloor heating

The underfloor heating system warms the air from the floor up to a height of 1.5–2 meters. At floor level, the temperature is 2–4 degrees higher than at head level — creating the most comfortable conditions: “warm feet, cool head.”

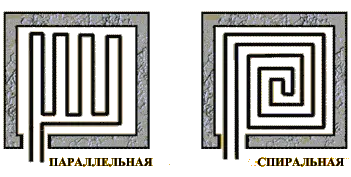

Pipe laying methods:

- Parallel (zigzag) — simpler, but temperature differences may occur between floor zones.

- Spiral — provides even heating, since the supply and return pipes are placed side by side.

Main parameters and installation stages:

- Standard pipe spacing — 20 cm; closer near exterior walls and windows.

- Pipes are laid on insulation (e.g., polystyrene foam).

- The system is filled with pressurized heat carrier to check for leaks.

- After testing, pipes are poured with concrete or cement screed.

- The best top layer is ceramic tile — it conducts heat most effectively.

Chimney

Modern chimneys: requirements for materials, shape, and insulation for boilers

Heating system automation

How automation maintains comfortable temperature and protects the heating system

Room for gas equipment

Standards for boiler rooms: from air inlets to minimum façade distances

Gas equipment – part 3

Efficient heating: boiler capacity calculation and an overview of alternative heaters

Gas equipment – part 2

Condensing boilers: how they work, efficiency, and when they pay off.

Gas equipment – part 1

Modern gas boilers: floor-standing and wall-mounted solutions for houses and apartments